Product 29/06/2023

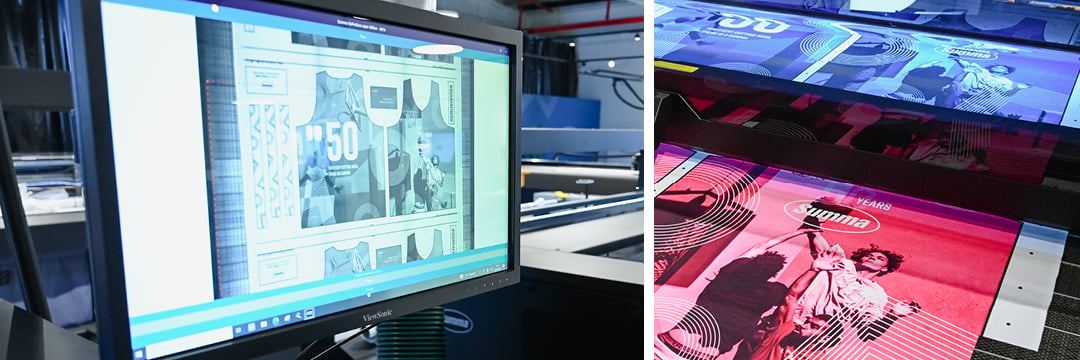

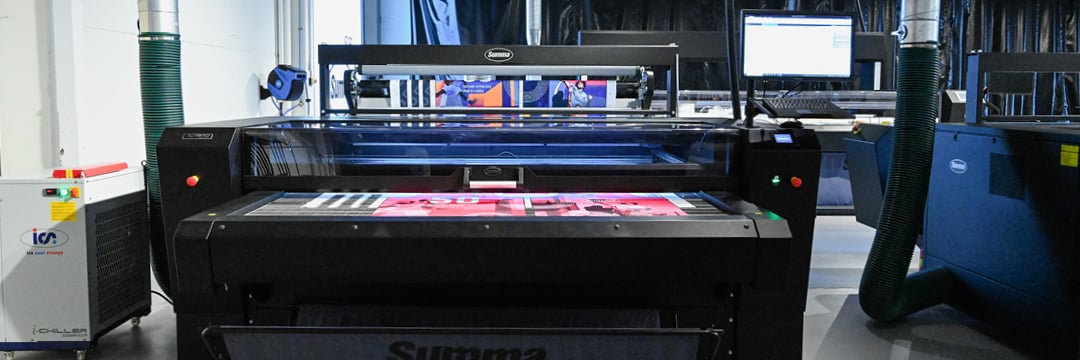

Within the industrial printing, cutting, and finishing industry, a well-thought-out production workflow is key. It increases capacity, reduces costs, and establishes a rapid throughput. In the last couple of years, the pressure to deliver more results in less time while still maintaining the same high quality has significantly grown. To achieve those high-quality results, it’s crucial to identify bottlenecks in your workflow.

Don’t know where to start? Summa’s here to help! Here are three possible workflow jams to watch out for and tips on how to turn them around:

Printers are generally faster than cutting machines. Knife-cutting technology, but also many laser brands, can barely keep up with the speed of traditional printers. This leads to cutting jobs queuing up.

Summa laser cutters can meet printer speed thanks to a unique advantage: our Vision Camera. The camera detects shapes automatically and cuts them on-the-fly. In other words, while the laser cutter is cutting, it’s simultaneously scanning and transporting the fabric.

Make our Summa laser cutter an essential part of your production workflow! Avoid a loss of time and increase your production capacity to one that, at minimum, equals your printing capacity.

Solution: Increase your yield using our cutting-edge Vision System

Whether you’re processing a very intricate design or keeping things plain and simple, it’s the quality of the result that matters. Mistakes, like fraying or distortions in the fabric, are not acceptable.

More traditional methods, like knife cutting, contain more risk of deforming your materials due to the friction produced when the knife comes into contact with the material. This will not be a problem with a laser cutter as a laser beam has no mass, so it won’t push, pull, or displace materials.

Cutting textiles has never been more qualitative and easier than with a Summa laser cutter. Cutting the edges of the synthetic fabrics results in perfectly clean and thinly sealed edges.

Maintaining the same high quality over a longer distance and in longer production runs is possible thanks to the highly stable laser beam a Summa laser cutter produces. Thanks to the stability of the laser, the beam stays focused from start to finish.

Solution: Level up your quality standards with our highly stable laser beam

When comparing the production efficiency of traditional cutting methods with that of the Summa laser, these points stand out:

Solution: Optimise the cutting process with Summa’s compact and fast laser cutters

Do you want to know more about how the Summa laser cutters can help your business solve workflow problems? Visit our laser cutter page or contact us!