Product 29/06/2023

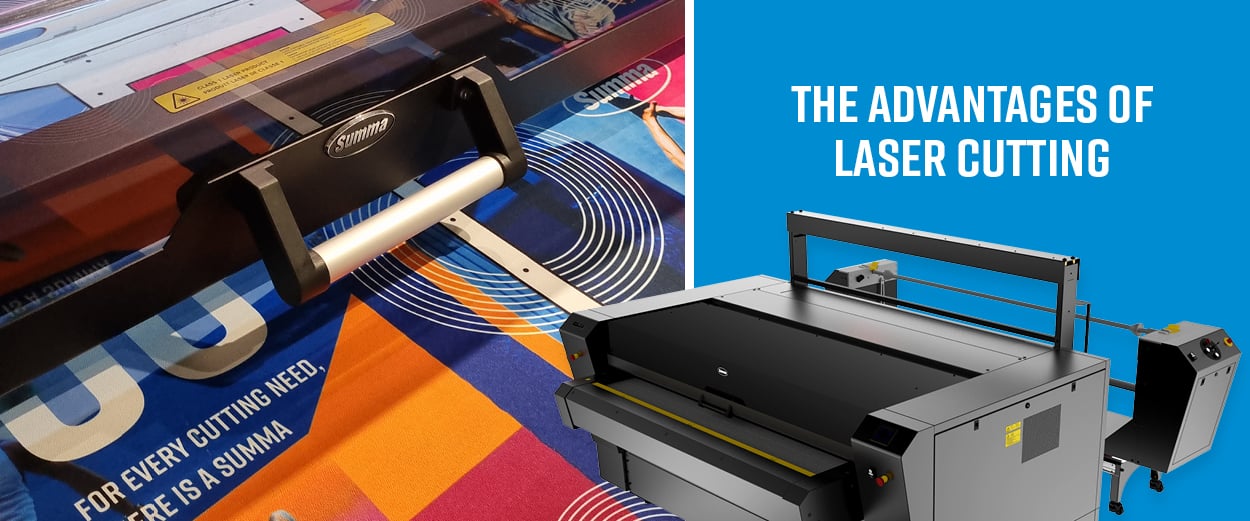

Choosing between knife and laser cutting depends on the specific requirements of the jobs you want to run. But what are those requirements? Summa offers both laser cutters, known as the L Series, and knife cutters, the F Series. Each system has its strengths depending on the job, the material, and the application. This article explains when we recommend laser cutting over knife cutting.

What is particularly striking is that laser cutters are incredibly fast compared to other cutting solutions on the market. Even knife-cutting flatbed systems will have difficulty keeping up with the laser cutters’ pace. In addition, laser cutting contributes substantially to the overall accuracy.

The distinctive features and benefits of laser cutters compared to knife cutters are outlined below.

One of the primary benefits of laser cutting lies in its superior accuracy compared to knife-cutting methods. Laser beams, having no mass, avoid pushing, pulling, or displacing materials when cutting. This enables precise handling of intricate details, such as fine textile cutouts, woodcutting, and engraving.

In general, laser cutting outperforms traditional knife cutting in terms of speed, especially when dealing with complex cuts. Unlike knife-cutting machines that require time to lower and rotate the knife into position, laser-cutting machines operate swiftly with the flip of a switch. Laser beats knife cutting in productivity and speed every time.

In addition, as there is only a laser beam to take care of, you are not bothered with any tool setup, which saves time and costs. So, if you are looking to increase production capacity and have the type of jobs for it, laser cutters are worth looking at.

Laser cutting requires little manpower due to laser technology being highly automated. An experienced machine operator still plays a significant role in the final quality but has much more operator comfort. The cutting speed and reduced manual labour save time and costs compared to knife-cutting methods.

This means that laser cutting is particularly advantageous in high-volume production areas where large quantities have to be cut, and little changes need to be made between different materials. Nevertheless, you don’t need a large production volume to benefit from a laser cutter: lower productions also benefit from the freed capacity!

The performance of a laser is generally measured by the quality of the cut. Notably, the quality of laser cutting stays constant as you don’t have any tool wear. What’s more, when configured with the appropriate settings and laser power, laser cutting avoids frayed edges and material deformation, something knife cutters cannot do. Thanks to the use of heat in laser cutting, material edges will be sealed together, providing a nice and soft finish, especially with synthetic textiles commonly used in sportswear.

Additionally, when it comes to processing stretch materials, laser cutters outshine knife cutters in both quality and finishing. Traditional knife cutters tend to struggle with flexible garments, causing pulling and distortion of the material, resulting in deformations. In contrast, a laser system with its contactless design is the perfect solution to cut polyester sportswear and soft signage.

Laser cutting involves no contact with the material, as a laser beam is just concentrated heat. That’s why it eliminates mechanical friction that could wear out tools and avoids any distortion of the cut material (fabric). Contactless cutting is especially advantageous in applications with delicate materials as they stay in place and do not get damaged.

Working out much finer details is a laser cutter benefit, allowing more unique applications to be processed, including perforation and marking. Summa laser cutters are exceptionally accurate when cutting from a roll and contactless cutting on a conveyor belt. Our tensionless roll-off winding system also eliminates any tension in the textiles before cutting, creating the perfect cut for your materials.

Laser is suitable for various techniques such as cutting, engraving, and marking. Laser marking is the process where a material - which can be anything from ceramics, plastics, metals, LEDs, rubber, graphic composites, fabrics, etc. - is marked or labelled with a black or coloured mark (depending on the material). Lasers can also engrave a wide range of non-metallic and non-PVC-containing materials such as wood, paper, acrylic, textiles, and leather.

The automated processes of laser technology decrease labour costs substantially by eliminating the need for manual interventions that would be essential when using knife-cutting equipment. Several features automate the production process of a Summa laser cutter:

Trace & Cut, for example, does away with the need for cutting files. Instead, a Vision camera system detects the cutting area thanks to a black outline and starts cutting. Another feature is the Barcode Workflow, which is part of the Summa GoProduce software ProPack. It enables you to cut an entire roll with different cutting jobs without operator intervention, as the barcode is quickly scanned, and the file is retrieved automatically.

By transforming cutting workflows with more efficient laser-driven solutions, businesses can gain greater control of their production processes. Summa laser cutters seamlessly integrate with various design software programs, facilitating their incorporation into diverse Print & Cut workflows. Data can be sent to the laser cutter from the printer automatically and efficiently, eliminating time-consuming data preparation.

To respond to and keep up with ever-changing challenges and trends, it is crucial to consider adjustments to production workflows and machinery. Given the constant rise in demand for printed textiles, optimised laser-cutting solutions become imperative. These solutions can help broaden businesses' signage portfolios, help them create more versatile applications, and meet more extensive demands.

If you want to know more about our laser cutters, visit our laser cutter page or contact us here. If you are curious about how Summa cutters can solve common bottlenecks in a production workflow, you might be interested in reading this article.